Key Points

- Traditional cladding system based on the double lock standing seam.

- Principally used in façade cladding, on flat or curved areas.

- Weather-tight from 25º of pitch and above if used in roofing.

- Attractive design layouts complement different architectural styles.

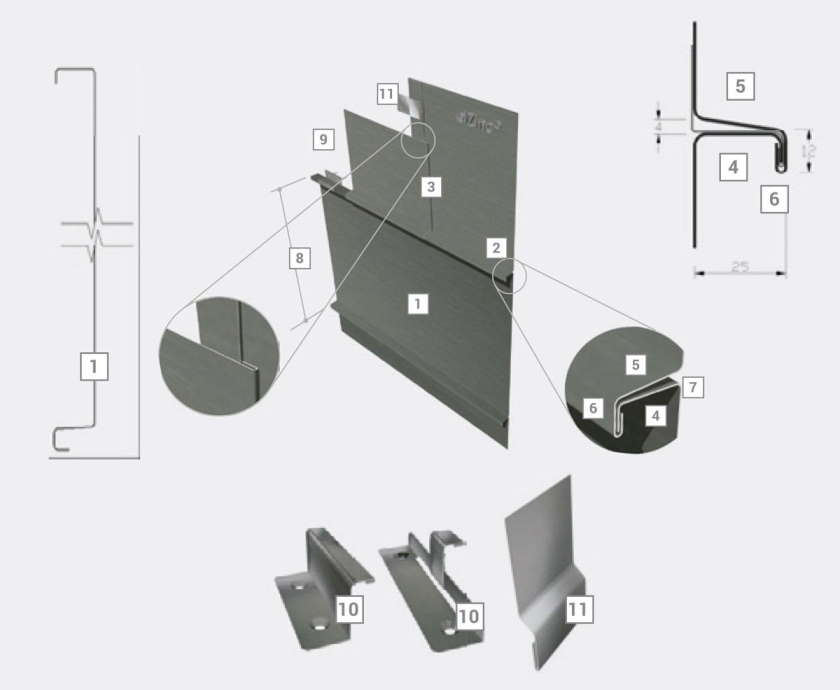

Basic System Information

- elZinc® angle standing seam roofing tray.

- Angle Standing seam joint (horizontal, vertical or set at an angle)

- Flat lock transversal joint

- Undercloak

- Overcloak

- Welt of angle seam

- Expansion gap at seam base

- Seam centres dimension, normally from 430 to 600mm

- Stainless steel ‘fixed’ clip – anchors the tray in position

- Stainless steel ‘sliding’ clip – allows longitudinal expansion

- Stainless steel flat lock clip – for clipping the transversal joints

Appearance

Angle seam façades exhibit fairly pronounced directionality – the longitudinal angle seam is more visible than the flat lock cross joints and so it dominates the aesthetic. The thin gauge zinc used can produce some degree of oil canning adding character to the façade. If desired, this can be minimised by using 0.8mm elZinc® in narrower panel widths of 430mm.

Fixing and dimensioning

The width of the trays should be dimensioned using the information available in designing with elZinc®.

Aesthetic considerations sometimes mean narrower trays than those required to resist wind loading are chosen.