Key Points

- Traditional cladding system using interlocking panels

- Principally used in façade cladding, on flat or curved areas.

- Weather-tight from 25º of pitch and above if used in roofing.

- Attractive design layouts complement different architectural styles.

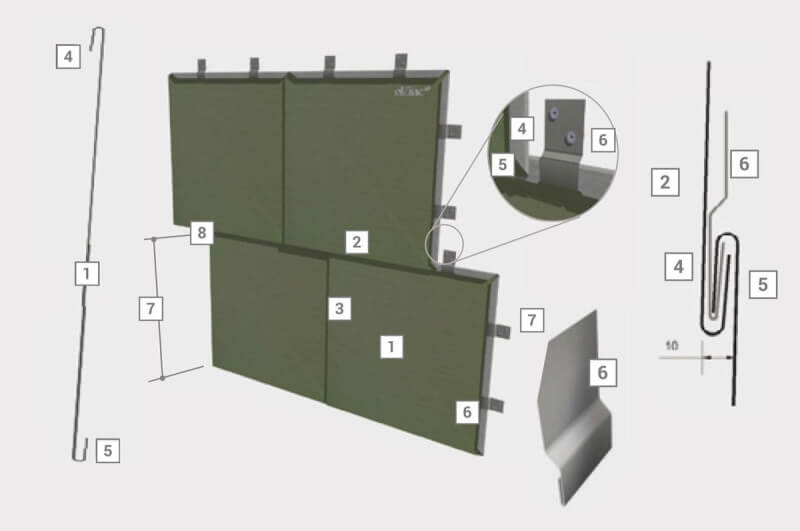

Basic System Information

- elZinc® flat lock shingle tray

- Flat lock dominant joint

- Flat lock transversal joint

- Undercloak

- Overcloak

- Stainless steel clip (can also be made of the same zinc as the cladding).

- Seam centres dimension, normally 430 to 600mm

Appearance

Depending on the layout of the joints, the system can either be directional or not. The seams themselves are very discrete, but they are highlighted by the shadows they cast in sunny weather, making them clearly visible especially on lighter finishes where the contrast is greatest.

This system is not profiled, so oil canning is normally less apparent than with the angle seam system.

Fixing and dimensioning

The width of the trays should be dimensioned using the information available in designing with elZinc®.

Aesthetic considerations sometimes mean narrower trays than those required to resist wind loading are chosen.

Design possibilities

As well as those designs shown for the angle seam for which rectangular shingles are employed, square flat lock shingles are often used but set at 45º. This arrangement can be either fully interlocked or set to leave a small overlap giving a more traditional artisan feel to the cladding.

Other designs are possible of course, as long as the shapes tessellate and the joints shed water correctly. As an example, a rhomboid design is illustrated below. Note how the same façade will change its apparearance according to the shadows cast by the flat lock joints at different times of the day.